OUR PRODUCTS

Layer Cage System

Layer cage equipment are the core facility in modern intensive egg production, designed to enhance breeding efficiency, reduce management costs, and ensure egg quality. The complete set of equipment significantly improves farming productivity, minimizes disease transmission, and supports the large-scale, high-efficiency development of layer farming.

Cages are manufactured with galvanized aluminum-zinc alloy panels and ultra-corrosion-resistant aluminum-zinc wires; all mesh panels are welded for smoothness, offering 3-4x longer lifespan vs. standard galvanized wire.

Sliding door of cage can satisfy birds eating in comfort, also make operating in cage easier during breeding process.

Feed Trough with V-Shallow design, reinforced structure with anti-spill and anti-clogging features to minimize waste and mold growth.

The bottom mesh with7° sloped mesh ensures gentle egg rolling onto the collection belt, reducing breakage.

700mm in ventilation area per tier to lower mortality rates.

Width | Depth | Height | Laying hens qty/cage | Activity space |

650mm | 625mm | 700mm | 9 | 451cm2 |

Duck Layer Cage System

Duck layer cage equipment is the core facility of modern intensive egg duck breeding. It improves the egg production rate, reduces the raising cost, and ensures the quality of duck eggs through scientific design. It is suitable for large-scale breeding farms.

Large-Scale High-Efficiency Farming:

Designed for industrialized mass production, our system enables rapid deployment with low construction costs and high profitability, empowering farmers to achieve efficient income growth.

Robust & Durable Structure:

Featuring an optimized H-frame design crafted from high-strength Al-Mg-Zn coated steel plates, the structure ensures exceptional stability, longevity, and low-maintenance operation for reduced long-term costs.

Ample Living Space:

Each cage measures 745mm (W) × 1580mm (D) × 640mm (H), accommodating 15–18 ducks with generous space to promote healthy growth.

Corrosion-Resistant Protection:

Premium PVC baffles effectively prevent duck-induced wear, significantly extending equipment lifespan and minimizing replacement expenses.

User-Friendly Management Features:

Equipped with steel pipes and reinforced steel feeding troughs, the system withstands frequent use while facilitating effortless daily inspections and management.

Species-Specific Behavioral Adaptation:

The one-side drinking/one-side feeding layout aligns perfectly with ducks’ natural physiology and behavioral patterns, enhancing their welfare and productivity.

Precision Egg Collection:

A scientifically calculated 7–9° sloped wire floor ensures gentle egg rolling onto collection belts, dramatically reducing breakage rates and associated economic losses.

Width | Depth | Height | Ducks qty/cage | Activity space |

745mm | 1580mm | 640mm | 18 | 654cm2 |

Breeder Layer Cage System

Breeder layer cage equipment is a modern breeding system specially designed for breeding chickens. Through scientific breeding management and environmental control, it improves the fertilization rate, incubation rate and quality of chicks. It is a key facility for the efficient production of breeding chicken farms.

Broiler Breeder Cage System

Broiler breeder cage equipment is a modern breeding system specially designed for the breeding of broiler chickens. Through scientific breeding management, accurate environmental control and automated operation, it improves the yield, fertilization rate and quality of chicks. It is a key facility for the efficient production of broiler chickens.

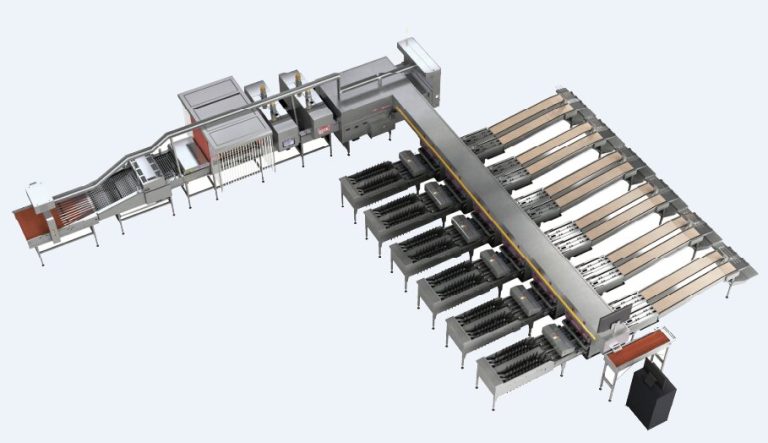

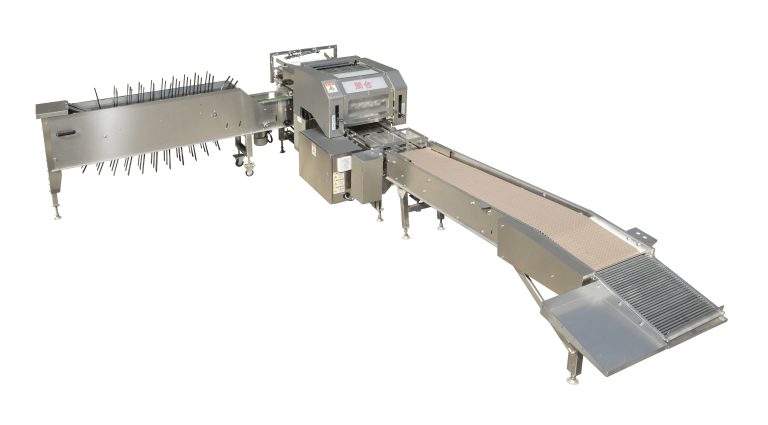

Egg Packaging System

Egg packaging equipment is the key link of the egg processing production line. It is used for automatic sorting, cleaning, grading, counting and packaging of eggs to improve packaging efficiency, reduce the breakage rate, and ensure product hygiene and safety. It is suitable for laying hen farms, egg processing factories and food distribution centers.

Egg packaging equipment is the key link to improve the value of eggs as well. Modernization and automated packaging have become the mainstream trend in the industry.

Compatible with central egg collection systems or clean egg production lines and maintains blunt-end-up orientation for tray loading. Suitable for 5×6 egg trays

High-Speed Operation:

Dual-mode processing capacity: 6,000 eggs/hour or 12,000 eggs/hour (configurable)

Precision Weight Grading:

Equipped with high-accuracy weighing system for precise egg classification. Meets diverse market requirements for egg specifications.

Gentle Tray Positioning:

Carbon tray mechanism ensures soft, accurate placement into designated slots. Minimizes breakage and maintains product integrity.

Reliable Performance:

Premium components with proven technology ensure operational stability. Reduced downtime for maximum production continuity.

Multi-Tray Compatibility:

Adaptable to various tray specifications and materials including:

Paper pulp trays, Plastic trays, Thermoformed packaging.

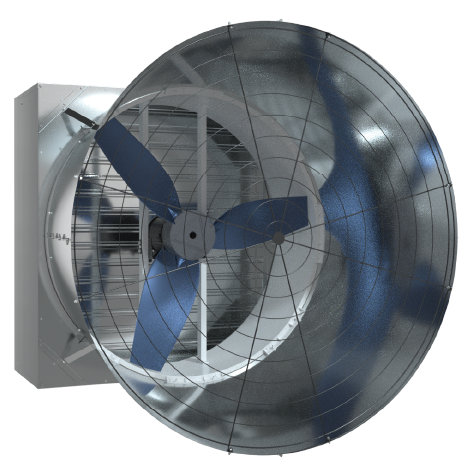

Ventilation and Environmental Control System

Ventilation and environmental control equipment is the core environmental management system of modern livestock and poultry farms. By accurately regulating the temperature, humidity, air quality and other key parameters in the house, it creates the most suitable growth environment for livestock and poultry, improves production performance, and reduces the risk of disease.

Universal Compatibility:

– Livestock houses (poultry/swine)

– Greenhouse applications (floriculture/vegetables)

– Custom ducting adapters available

Premium Drive System:

– TEAO-rated motors (10,000hrs MTBF)

– VFD-ready for precise speed control

– <0.5mm vibration amplitude at full load

Energy Smart Operation:

– Patented blade-motor coupling reduces energy loss

– 15-20% lower power consumption

– Eligible for ENERGY STAR® agricultural rebates

High-Efficiency Ventilation System:

– Optimized galvanized spiral blades

– 30% greater airflow vs conventional fans

– Effectively removes NH₃/CO₂ while maintaining O₂>19.5%

Military-Grade Construction:

– Hot-dip galvanized steel (275g/m² coating per GB/T 2518-2019)

– Corrosion resistance exceeds ISO 9223 C5 class

-30°C to 80°C operational range

Drinking System

Drinking water equipment is a key supporting facility for modern livestock and poultry farms. It provides clean and sufficient drinking water for animals, which directly affects the health level, production performance and breeding efficiency of animals. A scientific and reasonable drinking water system can significantly improve the water utilization rate and reduce the risk of disease transmission. It is an indispensable basic equipment for modern farms.

Adjustable Dosing System:

The Front part medicator with customizable concentration settings + integrated water meter for precise consumption tracking.

360° Trigger Nipples:

– Promotes poultry health with ergonomic drinking angles

– Reduces mortality rates by 18-22% (based on FAO 2022 field tests)

– Constructed with imported dual-seal components guaranteeing 15-year leak-proof performance

Self-Cleaning Pipeline:

– Automated flush cycles prevent biofilm/scale accumulation (meets WHO waterline hygiene standards)

– 63% reduction in manual cleaning labor (verified by third-party audits)

Advanced Pipe Engineering:

– UV-resistant stainless steel composite material

– Antimicrobial inner coating (tested against E. coli & Salmonella)

– Corrosion resistance exceeds ISO 8044 Level-5 requirements

Manure Treatment System (Fermentation Tank, Manure Drying)

The chicken manure treatment system is the core equipment for modern chicken farms to realize the resource utilization of manure. Through scientific treatment, chicken manure is transformed into organic fertilizer, biogas and other valuable products to solve the problem of environmental pollution and create economic benefits at the same time. The main treatment methods include fermentation tank treatment and air drying treatment, which are suitable for the needs of farms of different sizes.

Energy-Efficient Operation:

– Utilizes poultry house exhaust heat for drying (no winter heating required)

– 60% lower energy consumption vs conventional dryers

Rapid Processing:

– Reduces moisture content to ≤25% within 48 hours (fresh manure to ready-to-store)

Modular Smart Design:

– Customizable configurations for farm-specific needs

– Plug-and-play installation

Premium Performance

– Fully automated operation with IoT monitoring

– 80% lower maintenance cost compared to similar systems

– <1% annual failure rate (30,000h MTBF)

Environmental Protection

– Eliminates fermentation odors and pathogens during drying

– Reduces airborne dust particles by 60% (meets OSHA PEL standards)

– Prevents respiratory diseases in poultry and workers

Economic Benefits

– Dried manure stores indefinitely for seasonal fertilization

– 40% reduction in storage/transport costs

– Ideal raw material for premium organic fertilizer production (NPK content optimized)

Efficient Decomposition Process:

– Utilizes German EMI microbial inoculants + precision temperature control (45-65°C)

– Completes harmless treatment in 72 hours

– Final NPK content ≥8% (tested per NY 525-2021 standard)

Premium Construction:

– 304 stainless steel material contact surfaces

– Compact structure with 30% larger discharge capacity

– Multi-layer remediation design

Eco-Friendly Operation:

– Elevated exhaust system exceeds GB 16297-1996 emission standards

– Odor-control technology ensures zero detectable smell (50m radius)

– Forced-oxygen mixing with polyurethane insulation (heat loss <5%)

Automatic Operation:

– Single-dose microbial activation (no replenishment required)

– Self-maintained thermophilic phase (50°C+ for 5-7 days) effectively eliminates: Pathogens (99.9% reduction), Weed seeds, Parasite eggs

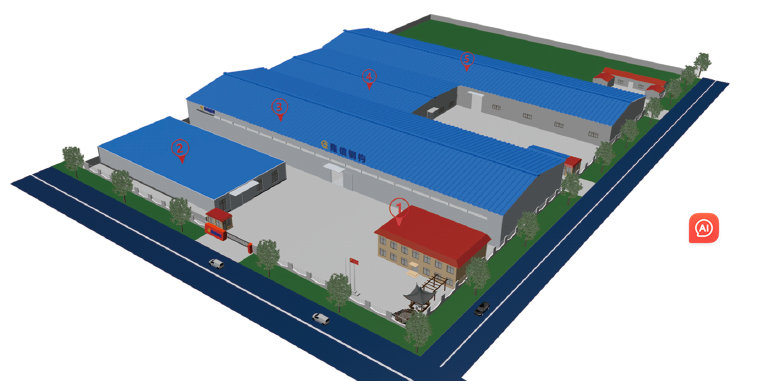

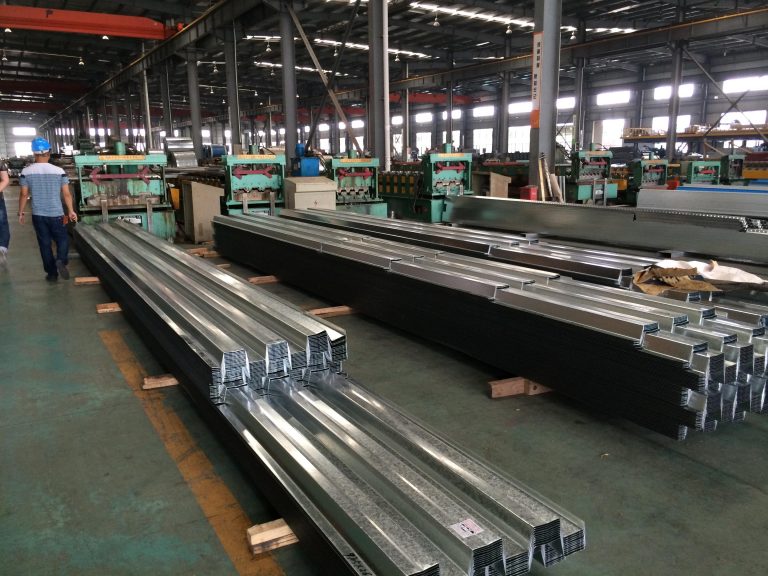

Kit House

Steel structure chicken coop is the mainstream construction form of the modern chicken industry. With its excellent performance and economic benefits, it is gradually replacing the traditional brick-mixed chicken coop. The system adopts a modular design concept and integrates the three functional modules of building structure, environmental control and breeding equipment, providing a comprehensive solution for the modern poultry industry.

Core Advantages:

✔ High Strength: Wind load resistance ≥0.6kN/㎡, snow load capacity ≥0.5kN/㎡

✔ Spacious Layout: Column-free design (adjustable span: 12-36m), facilitating mechanized operations

✔ Climate Control: Integrated intelligent ventilation/lighting systems for enclosed farming

✔ Cost Efficiency: Competitive construction costs (~¥300-600/㎡), 40% lower maintenance expenses

Structural Features:

– Main Framework: Hot-dip galvanized steel beams/columns, corrosion-resistant, service life ≥20 years

– Roof/Wall System: Double-layer color steel sandwich panels (polyurethane/PIR insulation), thermal conductivity ≤0.28W/(㎡·K)

– Modular Design: Bolt-connected prefabricated structure, 60% faster construction than traditional poultry houses

Applications:

– Modern stacked/tiered cage systems

– Large-scale farms (100,000+ birds capacity)

– Multi-climate zone adaptability (-30℃~50℃)

Development Trends:

→ PV-integrated roofing solutions

→ BIM-enabled prefabrication technology

→ Advanced high-strength lightweight steel materials